Leading companies in manufacturing, construction, oil & gas, and automotive industries rely on our cutting-edge digital twin solutions to drive efficiency, enhance performance, and reduce risks through real-time data insights and innovative technology.

At Kompanions, we offer trusted expertise in digital twin development, delivering innovative solutions that meet the unique needs of each client. With a proven track record of success across various industries, our tailored digital twin solutions drive efficiency and performance.

Our global reach allows us to support businesses worldwide, ensuring seamless integration and consistent results. Choose Kompanions to unlock the full potential of digital twin technology and propel your business forward.

Successfully Delivered

Team Members

Gurugram, Jaipur & Mohali

Our digital twin solutions help businesses reduce costs, make better decisions, improve operational efficiency, and boost productivity, empowering you to stay ahead in today’s competitive, data-driven landscape.

Digital twin solutions enable businesses to identify inefficiencies, optimize resource allocation, and eliminate waste, resulting in significant cost savings. By simulating processes and predicting potential issues, companies can proactively address challenges before they impact the bottom line.

With real-time data insights and predictive analytics, digital twin technology empowers decision-makers with the information needed to make informed, timely choices. This leads to better business strategies, minimized risks, and more precise planning for future growth.

By providing a comprehensive view of operations, digital twin solutions streamline processes, automate workflows, and reduce downtime. This results in enhanced operational efficiency, allowing your business to achieve more with fewer resources and greater precision.

Digital twins improve productivity by offering a digital replica of your operations, enabling continuous monitoring and optimization. With predictive maintenance and real-time insights, teams can focus on high-priority tasks, ultimately driving increased output and higher performance levels.

At Kompanions, we offer personalized digital twin services that address the unique needs of your business. Our solutions enhance operational efficiency, reduce costs, and deliver real-time insights for optimal decision-making and performance.

Prepare workers for real-world risks with VR work at height safety training. This immersive simulation teaches fall prevention, proper equipment use, and emergency response. Enhance awareness, reduce workplace accidents, and ensure OSHA compliance with risk-free virtual reality training for high-rise construction, maintenance, and industrial environments.

CONTACT US

We provide industry-specific digital twin solutions that cater to manufacturing, energy, automotive, and more. Our expertise in each sector enables us to design and implement digital twins that address unique challenges, improve process efficiency, and drive innovation, ensuring that every solution is aligned with your business goals.

CONTACT US

Our predictive maintenance services leverage digital twin technology to monitor equipment in real time, predict failures, and schedule maintenance before issues arise. This proactive approach reduces downtime, extends asset life, and lowers repair costs, while providing data-driven insights to improve overall operational efficiency.

CONTACT US

Using advanced 3D visualization, we create interactive digital twins that provide real-time insights into your systems. By simulating real-world conditions, we allow businesses to test and optimize designs, improve processes, and enhance decision-making, ensuring a more efficient and productive operation across industries.

CONTACT US

We help businesses transform their manufacturing operations with smart factory automation powered by digital twin technology. By integrating sensors and real-time data, we create dynamic simulations that optimize production lines, reduce waste, and enhance performance, resulting in smarter, more efficient factory operations.

CONTACT US

Our digital twin solutions for product lifecycle management help track and optimize the entire lifecycle of a product, from design to post-launch maintenance. By using real-time data and simulations, we enable businesses to make informed decisions, streamline development processes, and ensure long-term product success and sustainability.

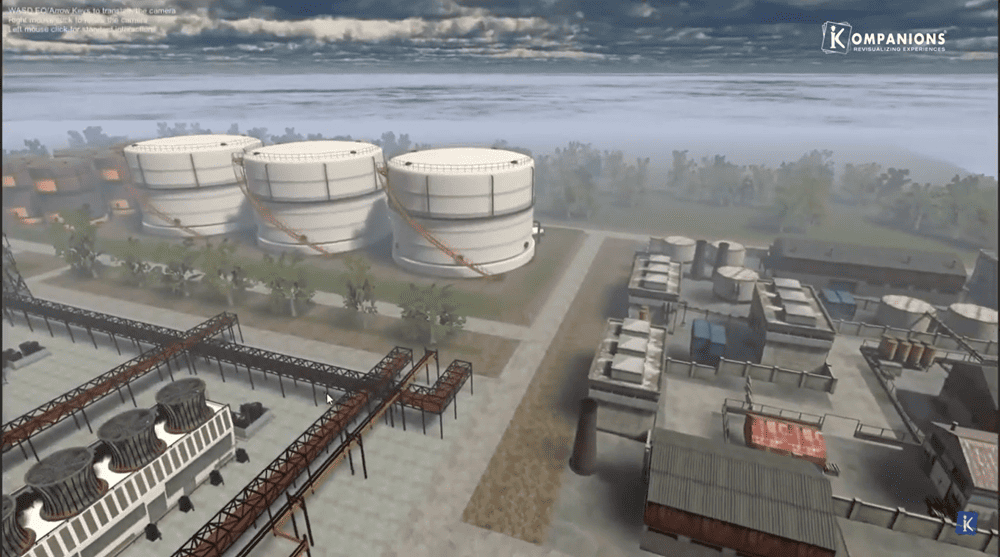

CONTACT USKompanions' industrial digital twins services are transforming industries such as manufacturing, automotive, energy, construction, aerospace, and many more. Our tailored solutions empower industries to drive efficiency, innovation, and sustainability, ensuring a competitive edge in today’s fast-evolving market.

Digital Twin as a Service is revolutionizing industries by offering scalable, flexible solutions that reduce costs, improve efficiency, and provide real-time insights, enabling businesses to stay competitive and innovate continuously.

Discover our latest blog posts on digital twin solutions, offering expert insights, real-world use cases, and how digital twin technology is revolutionizing efficiency and performance across industries.

The oil and gas industry operates in a high-risk, high-stakes environment where safety, efficiency, and cost-effectiveness are paramount. Digital twin oil and gas solutions are transforming the sector...

Read More

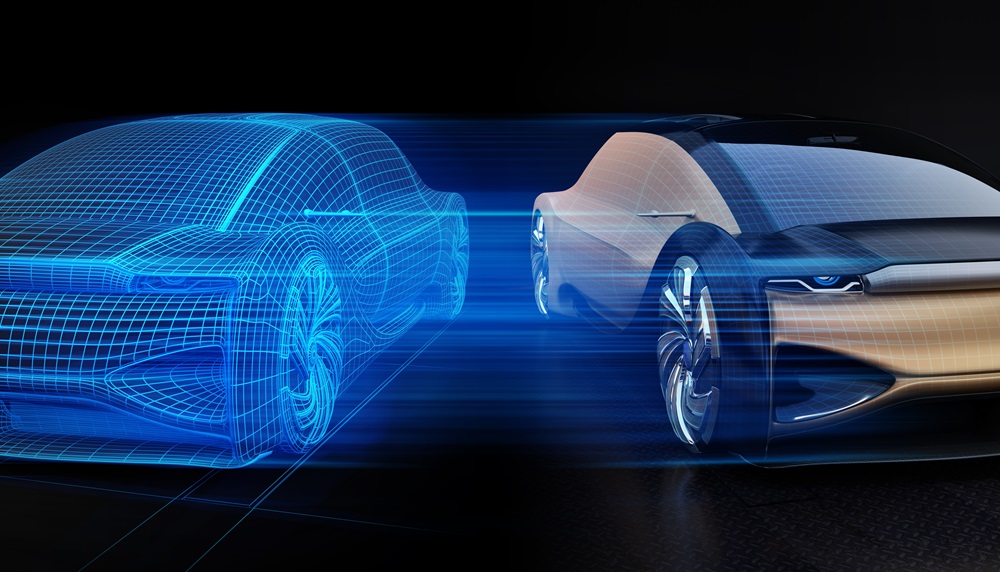

Envision a world where manufacturing is perfect, supply chains are dynamic, and cars can predict failures. Digital twins in the automotive industry have been changing the dynamics of the industry rapidly in...

Read More

Global industries are striving toward digital transformation. Enterprises are trying on nearly all the advanced technologies to speed up their digital transformation journey.Digital twins in manufacturing will not just help manufacturers create..

Read MoreDigital twin development enhances industrial automation by providing real-time monitoring, predictive maintenance, and process optimization, allowing businesses to automate tasks, reduce errors, and improve efficiency across operations.

Digital twin consulting improves operational efficiency by analyzing real-time data, identifying bottlenecks, and providing insights that help optimize workflows, reduce downtime, and enhance resource allocation within manufacturing processes.

Industries like manufacturing, automotive, construction, energy, and aerospace benefit significantly from 3D digital twin solutions, improving design, simulation, predictive maintenance, and real-time operational monitoring.

Digital twin as a service offers scalable, subscription-based models that provide enterprises with virtual replicas of physical assets, enabling real-time data analysis, remote monitoring, and improved decision-making without heavy upfront costs.

Challenges include high initial setup costs, data integration complexities, ensuring data accuracy, and the need for continuous updates and maintenance to maintain the digital twin’s relevance and functionality.

Costs vary depending on the complexity, scale, and customization of the solution. Key expenses include development, integration, software, hardware, and ongoing maintenance, with potential savings in long-term operational efficiency.

Key features include expertise in your industry, customizable solutions, real-time data analytics, strong security protocols, seamless integration, and robust customer support to ensure the solution meets your business needs.

Share your details and allow us to help you explore inventive ways to usher in a whole new world of immersive realities. Let's build something extraordinary, together.