Virtual Reality for Heavy Equipment Operator Training

Qualified heavy equipment operators are one of the key demands of sectors like logistics, construction, and mining. Proper training on the equipment is essential in ensuring smooth operations.

Conventional training methods, however, have some drawbacks, like safety hazards, limited access, and high cost. The training process with its state-of-the-art features. The safety and cost savings offered by VR for heavy equipment training are rendering it a widely used tool in industries that are extremely accident and hazard-prone.

This guide offers a detailed overview of the implementation of VR in various industries to be used in the training for bulldozers, excavators, cranes, forklifts, and backhoes.

The Call for Innovation in Heavy Equipment Training

Virtual reality has left its imprint on most of the fields of the industry in recent decades, and heavy equipment training is also not an exception. Traditional modes of training such as apprenticeship schemes and in-plant construction are potentially unsafe, time-wasting, and costly.

The chances of accidents in training with such equipment are very high and often lead to causing risk to employees’ lives. In addition, the volatility of real-world situations makes it even more difficult to offer consistency in training employees.

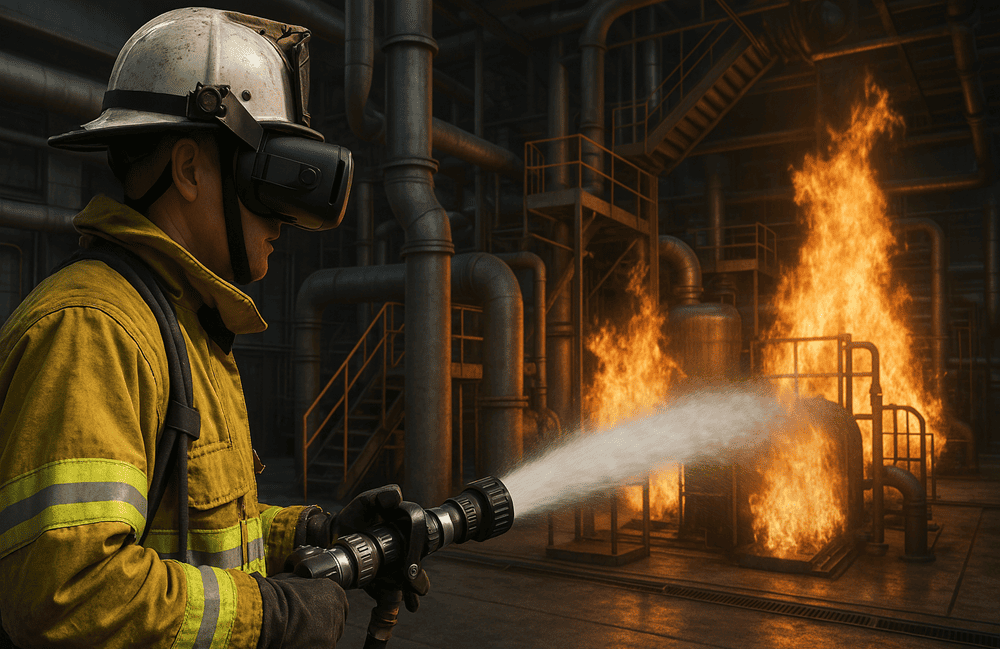

VR heavy equipment training addresses all of these issues by presenting a controlled, immersive learning situation.

Trainees can be trained using this equipment with challenges like having to react to surprise situations, establishing muscle memory without risk of harm, and honing elaborate manoeuvres through learning-by-doing within an immersive simulated environment provided through VR safety training for workplaces.

It also provides standardized training modules, guaranteeing consistent, high-quality instruction.

1. VR for Excavators Training: Digging into Proficiency

Mining and construction projects are highly dependent on excavators. VR excavator training simulates real-life digging, grading, and material handling with complex machinery in a secure and controlled atmosphere where trainees can rehearse safely.

Excavator simulation mimics conditions on the job, including diverse weather, different soil conditions, and different site configurations.

VR for Heavy Equipment Training for excavators offers several benefits, such as:

- Risk-Free Learning Environment

- Cost Savings

- Better Retention & Skills Building

Employees can practice on real-life-like models and get instant feedback about their performances. VR offers consistent movement towards immersive equipment training, making it perfect to be adopted in multiple industry sectors.

2. VR Bulldozers Simulator: Breaking Barriers of Skill

Bulldozers are a basic equipment for grading, site preparation, and haulage. VR bulldozer simulator offers a realistic and interactive learning platform where operators learn to perform a range of operations such as leveling, pushing, and contouring. The operations of the VR bulldozer simulator are:

- Realistic Controls

- Scenario-Based Training

- Performance Analytics

VR Training in bulldozer operation facilitates the simulation of difficult terrains and complicated operations, which better equips the operator to manage hard-to-access environments. It also leads to improved construction safety VR practices.

Boost safety & efficiency with VR training for heavy equipment operators. Cut risks, save costs!

Upgrade Your Training Now3. VR Forklift Simulator: Elevating Safety Levels

Forklifts are an integral part of factories and construction sites. They are mostly used to lift, stack, and move materials.

VR forklift simulator offers a safe and cost-effective way to train employees to carry out various operations in real-world situations. Some of the significant benefits of the VR forklift simulator are:

- Safety Compliance

- Multi-Scenario Training

- Reduced Operational Costs

VR forklift training is safety-oriented, with trainees experiencing lift security techniques and learning potential dangers. This is one of very very important aspects of VR workforce development.

4. VR Backhoe Operator Training: Simulation Versatility

Backhoes are multi-functional equipment that find use in excavations, trenching, and transporting materials. VR backhoe operator training is the simulation of actual driving experience with such machinery, when operators learn various operations within a safe and controlled environment.

Through the use of Hands-on simulation training through VR, operators are exposed to a vast array of scenarios that enable the acquisition of rapid decision-making and problem-solving capabilities.

This degree of preparation directly equates to greater safety and efficiency on actual construction sites.

5. VR Cranes Training: Enhancing Safety and Accuracy

VR crane training has changed the dynamic for crane training in recent years. The technology offers a realistic crane operation simulation allowing workers to acquire various skills like setting, lifting, and swinging the loads. VR features for crane operator training include:

- Hands-On Simulation Training

- Load Balancing Techniques

- Construction Safety VR

VR for Heavy Equipment Training in crane operations focuses on safety, enabling trainees to learn safe lifting practices and prevent potential hazards. This is critical to preventing hazardous accidents.

The Future of VR in Heavy Equipment Training

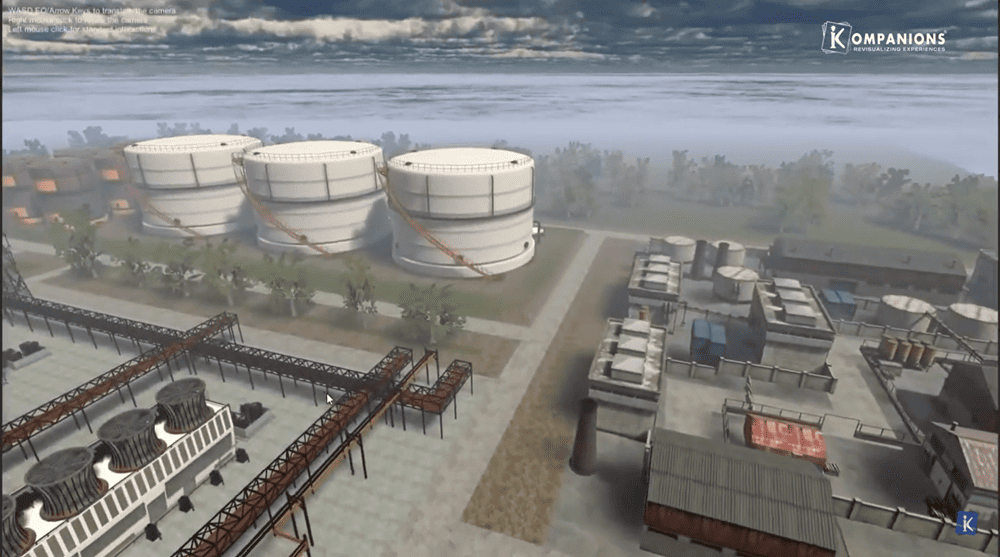

The future for VR training of heavy equipment looks good with ongoing technology improvements and expanding uses across industries. Incorporating construction project digital twins and predictive maintenance into VR simulation will further augment training efficiency and operational effectiveness.The mining VR is also seeing tremendous growth, with VR utilized for mine planning, operator training, and safety simulations.

Augmented reality in construction training is also becoming a useful tool, as a supplement to VR, by projecting digital information onto the real world. This has applications in on-site training, inspection, and maintenance.

VR construction safety is becoming more and more crucial to industries to minimize accidents and enhance working conditions. Through offering realistic training sessions, VR is assisting in developing a safer and more productive workforce.

Key Takeaways

VR for heavy equipment training is rapidly changing operator training and skills acquisition. In delivering safe, extremely interactive learning and an economical experience, VR is serving fundamental industry demands and facilitating safer, more efficient labor.

Revolutionize heavy equipment training with VR. Safer, faster, and more cost-effective skill development

See VR Training in ActionIn advancing technology, we can imagine VR use increasing further in heavy equipment training for better safety, productivity, and labor development.