Poor Manual Handling: Why VR is the Key for Safety Training

Manual handling tasks are routine in industries like construction, manufacturing, oil and gas, power, automotive, and marine. However, when performed incorrectly, they can lead to serious injuries, decreased productivity, and increased costs.

Traditional training methods often fail to prepare workers for real-world challenges. Enter virtual reality, a transformative approach to manual handling safety training that offers immersive, effective learning experiences.

Understanding the Impact of Poor Manual Handling

- Improper lifting techniques: Bending at the waist instead of the knees.

- Overestimating personal strength: Attempting to lift loads that are too heavy.

- Lack of planning: Not assessing the load or the path before lifting.

- Ignoring ergonomics: Failing to use tools or aids that can reduce strain.

These errors can result in musculoskeletal disorders, back injuries, and other health issues, leading to lost workdays and increased compensation claims.

The Limitations of Traditional Training

Conventional training methods, such as classroom sessions or instructional videos, often lack engagement and fail to replicate real-life scenarios. Workers may not retain critical information or understand how to apply it in practical situations.

This gap in training effectiveness can contribute to ongoing safety issues.

How VR Enhances Manual Handling Training

Manual handling training with VR offers several advantages over traditional methods:

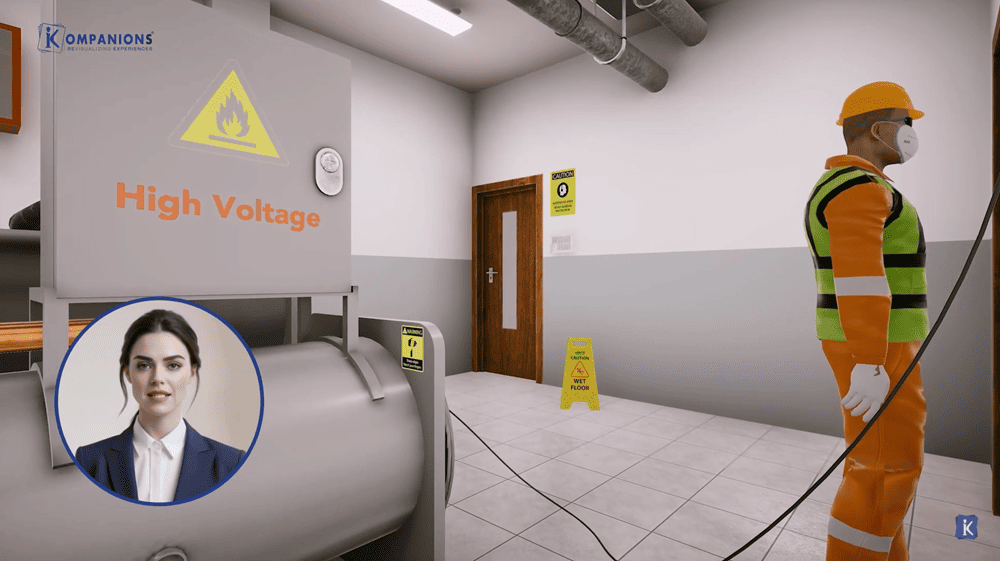

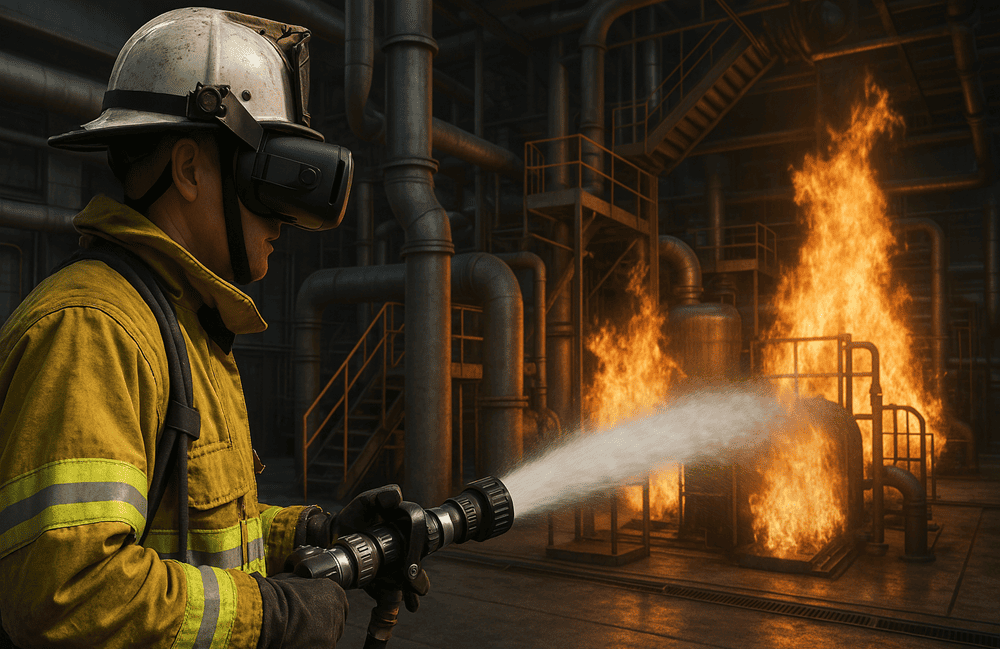

- Immersive Learning: VR creates realistic simulations where workers can practice lifting, carrying, and moving objects in a controlled environment.

- Immediate Feedback: Trainees receive real-time feedback on their techniques, allowing for quick corrections.

- Safe Environment: Workers can make mistakes and learn from them without the risk of injury.

- Engagement: Interactive scenarios increase engagement and knowledge retention.

A study from Capability Group has shown that VR-trained employees are better equipped to handle real-world challenges, leading to a significant reduction in workplace injuries and associated costs.

Implementing VR in Industrial Settings

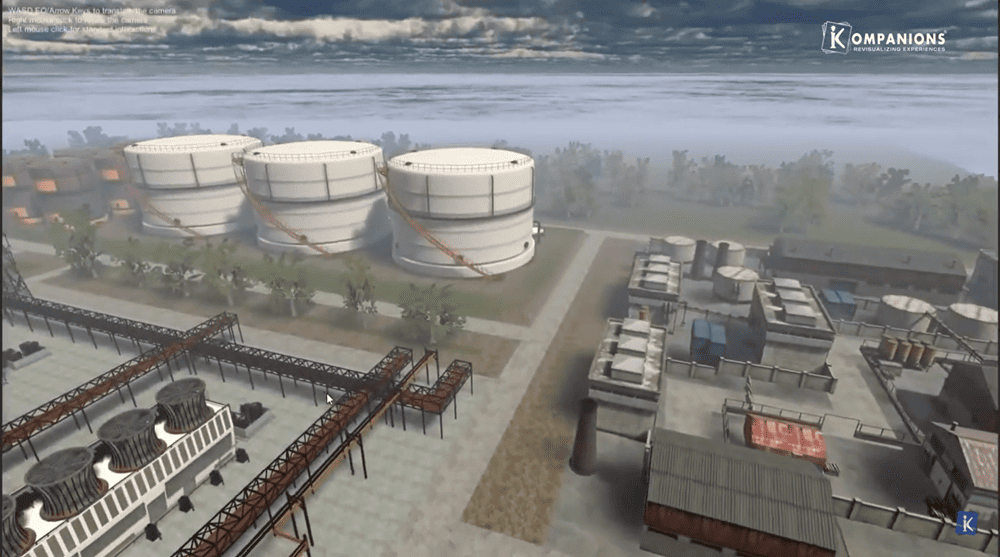

For industries dealing with heavy machinery and complex operations, VR provides tailored solutions:

- Construction: Simulate lifting and transporting materials on uneven terrain. (VR for construction safety)

- Manufacturing: Practice handling components in assembly lines. (Role of digital twins in manufacturing)

- Oil & Gas: Train for equipment handling in hazardous environments. (AR in the Oil & Gas)

- Power: Prepare for tasks involving heavy cables and transformers. (AR for Nuclear Power Plants)

- Automotive: Learn safe methods for moving vehicle parts. (AR in Automotive Industry)

- Marine: Rehearse loading and unloading procedures on vessels. (VR for Marine Safety Training)

By integrating VR into workplace safety training, companies can address specific challenges unique to their operations.

Benefits of VR-Based Manual Handling Training

The adoption of VR in safety training brings measurable benefits:

- Reduced Injury Rates: Enhanced training leads to fewer accidents.

- Cost Savings: Lower compensation claims and less downtime.

- Improved Compliance: Meet regulatory standards more effectively.

- Enhanced Productivity: Well-trained employees perform tasks more efficiently.

Want to reduce injuries and boost efficiency? Experience VR-based manual handling training firsthand.

Get a Free DemoMoreover, VR makes hazardous environment training safer, allowing workers to experience and respond to potential dangers without real-world risks.

Addressing Common Manual Handling Mistakes with VR

VR training can specifically target and correct frequent errors:

- Poor Lifting Technique: Simulations teach correct posture and movement.

- Overestimating Strength: Scenarios demonstrate the importance of assessing load weight.

- Inadequate Planning: Exercises emphasize the need for route and load assessment.

- Ignoring Ergonomics: Training highlights the use of tools and aids to reduce strain.

By focusing on these areas, VR promotes effective manual handling practices.

The Future of Safety Training

As industries evolve, the integration of industrial VR solutions becomes increasingly essential. Companies that invest in VR training demonstrate a commitment to employee safety and operational excellence.

With the ability to simulate a wide range of scenarios, VR stands out as a powerful tool in reducing the hidden cost of poor safety training.

KOMPANION offers cutting-edge VR safety training solutions tailored to the unique needs of core industries. Our programs are designed to enhance learning, improve safety outcomes, and boost productivity.

Explore how our solutions can transform your training approach and safeguard your workforce.