AR in Oil and Gas: The Game Changer for Worker Safety

One of the smartest asset investments by the oil and gas sector has turned out to be Augmented Reality. From the consumer market, AR has taken a giant leap into the services sector and is a boon for the ever-expanding oil and gas sector along with its ever-expanding safety concerns.

• According to IOGP, 1.01 deaths occur for every 100 million work hours in the oil and gas sector.

• 0.92 injuries were reported per one million working hours.

• This leads to almost 703 lost working days per annum.

Sector Overview

The global oil demand fell in 2020, resulting in an 8% revenue loss. The soft demand and the rallying equity markets further choke the supply.

- Global energy demand is now projected to increase by approximately 25% by 2040. (Institute for Energy Research)

- Renewable energy consumption is expected to grow by an average of 2.3% per year from 2015 to 2040, making it the fastest-growing energy source. (EIA.GOV)

- The United States holds the largest share of global refining capacity, accounting for 18.6% of the world's total. (IEA.ORG)

Keeping up with the current demand requires additional personnel. This mammoth workforce needs to be safe as well as coherent. As the oil price crashed in March, aggressive human-machine collaboration has been looked into by the sector.

From increasing efficiency and collaboration to maintaining performance, Augmented reality technology has already begun seeping deep into the oil and gas industry.

The benefits of augmented reality for businesses are significant, as this technology revolutionizes the way companies operate and engage with their customers.

AR for Oil and Gas Plant Safety

Wearable technology in the oil and gas industry is a promising development and a relief for the industry players. A major concern for the oil and gas industry is personnel safety as well as paraphernalia protection.

From predictive safety to digitally overlaid training sessions, AR has contributed to a safety surge.

• Goldman Sachs has predicted the augmented reality in the oil and gas sector to become $80 Billion by 2025.

• An ABI research has concluded that 17% of the global shipments of smart glasses were for the oil and gas sector.

This shows that many industry players are taking an interest and putting sufficient investments into this tech. Industry mammoths like British Petroleum, Chevron, and General Electric have already integrated AR into their safety solutions.

• State Grid is using AR-powered hard hats with temperature checks and hearing protection.

• Shell is using AR visors with infrared cameras.

• Baker Hughes is using AR-enabled smart helmets that overlay maintenance information.

• GE Oil Company has deployed AR-enabled personnel protection kits.

• Chevron has collaborated with Microsoft Hololens to dissipate better information to its technicians.

In a tech-driven era where digital transformation is paramount, AR is leading the way in oil and gas plant safety.

Use Cases of AR for Oil and Gas Plant Safety

Discover how augmented reality revolutionizes gas plant safety, enhancing situational awareness and minimizing risks in hazardous environments.

1. Head-mounted displays

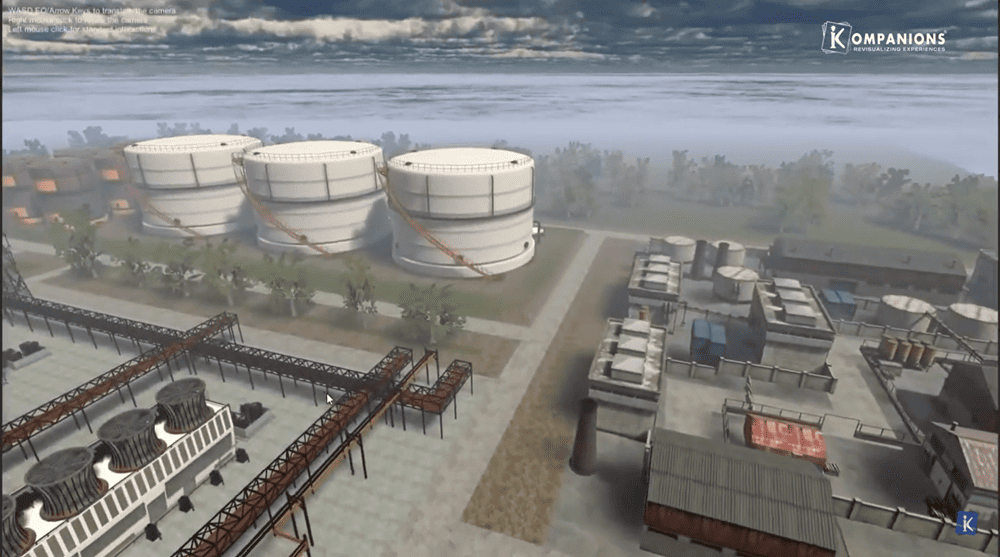

Head-mounted displays and smart glasses are the most commonly used wearable technology in oil and gas plants. These devices can project information about the apparatus that the personnel is operating.

Or give detailed maintenance information about any abrupt developments that might occur.

2. Sensor-driven predictive safety

Getting contextual data for maintaining personnel safety and remotely guiding the work is made simple through this. This also helps in resource planning and strategizing in real time.

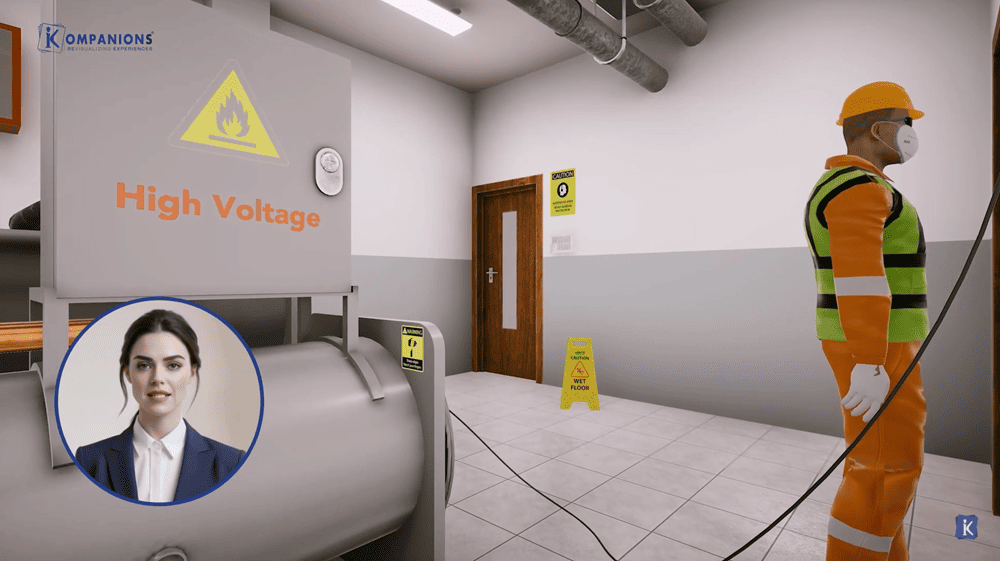

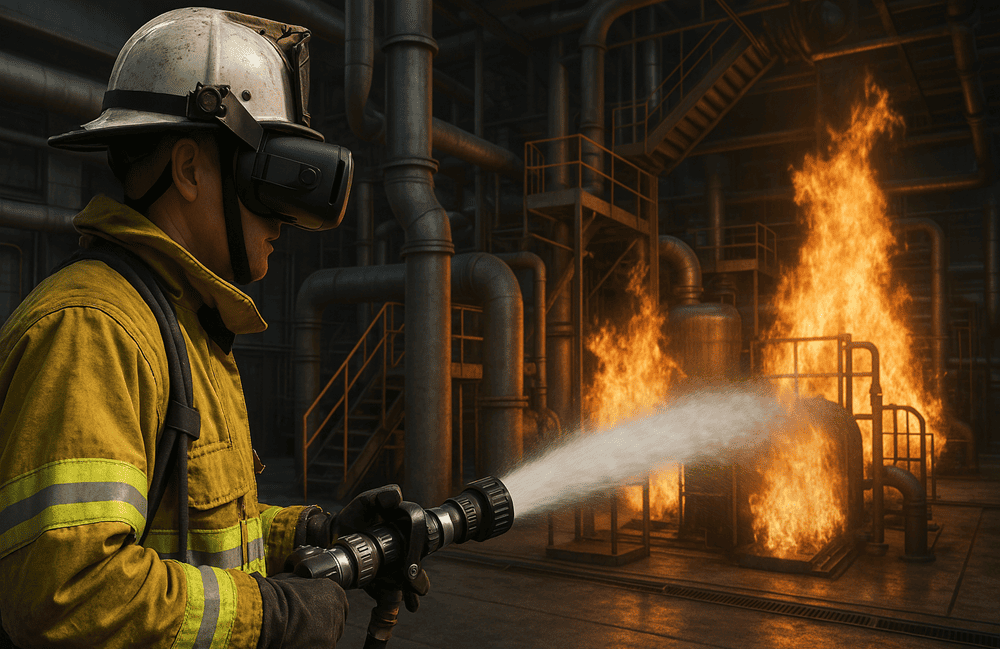

3. Training and on-site guidance

AR-enabled virtual lessons through virtual hazard training were the initial augmented reality development services in this industry. This has proved to be the most viable solution for training. The immersive experience definitely helps.

On-site guidance and remote work approval lubricates the workflow and enhances efficiency.

4. Overlays

This is crucial during maintenance and other unforeseen situations. The on-site worker can get all the information he needs without being distracted to another device.

Overlaying the real world with digital projections is the definition of augmented reality and definitely the best benefit for gas plant safety.

Looking Ahead

• The global AR market will reach $76 Billion by 2030.

• The market will accelerate at a 24% annual growth rate.

• By 2027, the AR market in the oil and gas sector is expected to reach $943.4 Million

• The market will experience a CAGR of 27.4%.

Enhance safety and efficiency in oil & gas with AR. Explore the game-changing impact today!

Book A DemoAccording to industry professionals, the adoption of immersive technology for industrial use will be as common as smartphone usage by 2025. One of the earliest adopters is the oil and gas industry.

The total capital expenditure can be cut down by 25% by adopting AR/VR by the oil and gas industry according to McKinsey.

With India’s growing energy needs, a bigger workforce will emerge in the coming years. Through AR in oil and gas safety adoption, the companies can be assured that efficiency is maintained while safety remains uncompromised.