How VR Makes Hazardous Environment Training Safer?

The safety and trust of the worker in emergencies, risk, and operations form the chief concern of contemporary high-risk industries like construction, manufacturing, oil & gas, etc.

Therefore, the workers in these employment sectors need strict training regimens for accident and injury-free work. Traditionally, these use classroom training, guides, and practice drills to share knowledge.

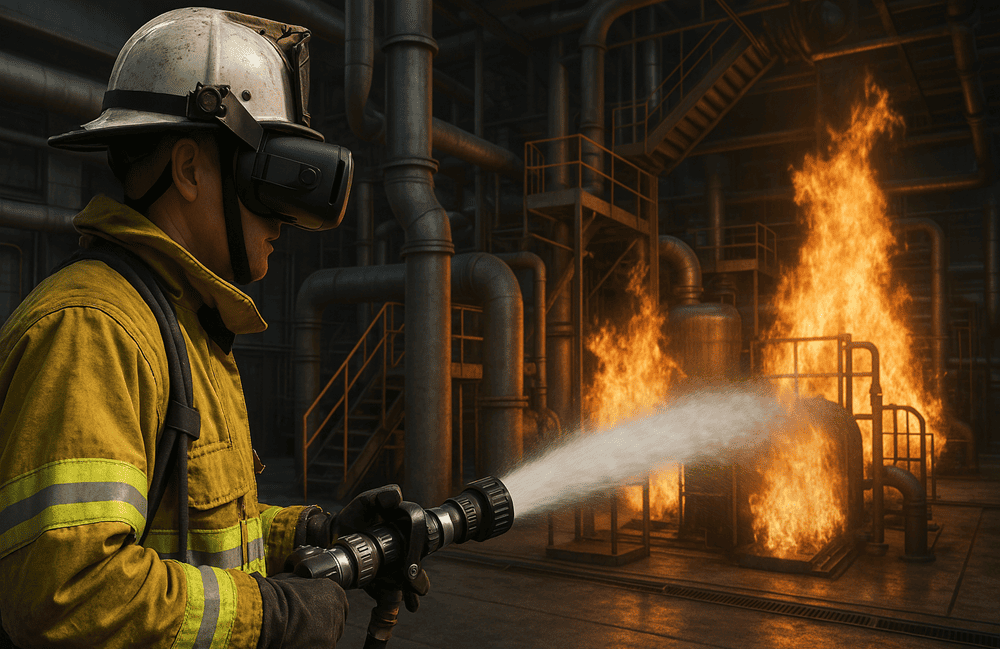

The amazing innovations in technology brought about by virtual reality are now changing the realities of safety training. VR training for hazardous environments gives the possibility for the future to prepare them with adequate skills and confidence to work in dangerous environments effectively.

This guide offers an in-depth analysis of how technological advancements like AI, and AR/VR have revolutionized high-risk industries like construction safety and many others.

The Need for VR Training in Hazardous Workplace Training

Industrial safety training through virtual reality is essential in industries that employ workers who are exposed to dangers such as equipment malfunctions, poisonous materials, and dangerous work operations.

Regular training, such as classroom learning and experience in the job setting, could prove inadequate in providing workers with appropriate skills for addressing emergencies.

Industrial safety with virtual reality provides an authentic yet risk-free situation in which training and reinforcement of important safety measures are conducted.

Key Benefits of VR Safety Simulations

Virtual reality training for hazardous environments has proven to be a game changer in industries prone to high accident rates. By providing life-like simulations of threatening situations, VR efficiently trains employees to face any kind of challenge without risking their lives.

Some of the major benefits offered by VR training for hazardous environments include:

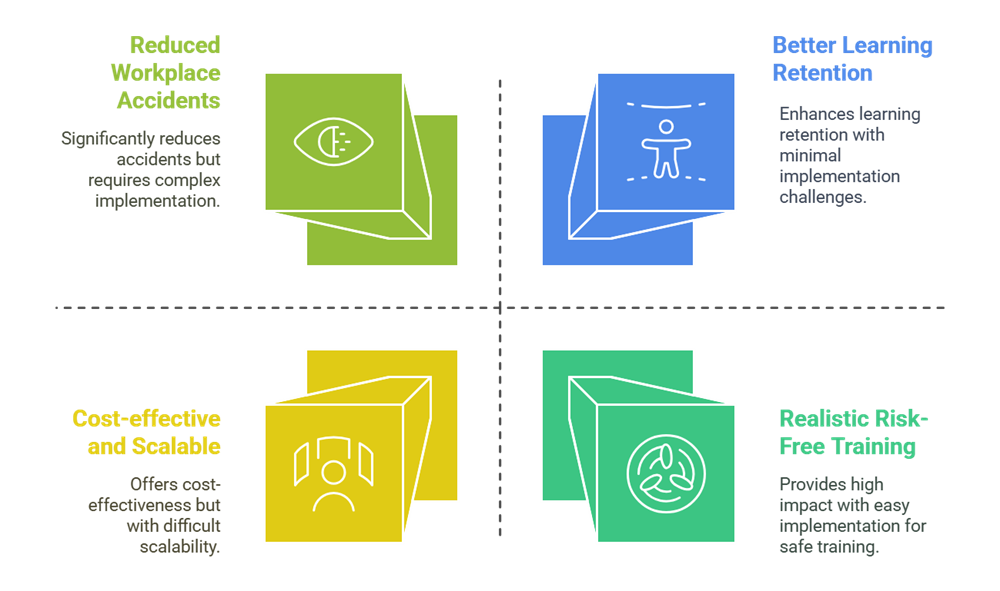

Better Learning Retention

- Immersive safety training enhances knowledge retention rates relative to conventional learning methods. The capacity to experience situations within a risk-free environment enhances learning results.

- Interactive simulations enhance hands-on training, facilitating students to implement knowledge better in actual situations.

Reduced Workplace Accidents

- VR accident prevention techniques allow employees to repeatedly practice emergency response training repeatedly, ensuring they can react appropriately in real-life situations.

- Live feedback and performance monitoring aid in the determination of weak spots and enhancing response techniques prior to accidents.

Realistic Risk-Free Training

- VR risk assessment tools expose workers to hazardous situations without putting their lives in danger. This fosters confidence and preparedness for real-world hazards.

- Adaptive learning environments modify levels of difficulty according to user performance to provide a customized and incremental training experience.

Cost-effective and Scalable

- Unlike physical training setups, VR industrial solutions reduce costs associated with materials, safety gear, and facility rentals. Companies can train multiple employees simultaneously with minimal investment.

- Remote availability enables employees to train remotely, lowering travel expenses and logistical burdens.

Strategies for Employers to Implement VR Training:

Businesses in the field of high-risk areas have started realizing the importance of VR training for safety in recent years. VR training for hazardous environments has changed the face of the training scenario by providing great benefits and eliminating the risk of accidents.

To effectively implement VR Training for Hazardous Environments in their safety programs, employers can employ the following strategies:

Knowing the Requirements:

- Identify some of the workplace hazards and dangers.

- Identify various employee groups' training needs.

- Examine the current training programs and understand the areas for improvement.

Integrating High-Quality Equipment in the Program:

- Choose controllers and VR headsets that are easy to use.

- Select software that provides realistic simulations and engaging learning experiences.

- Consider partnering with experienced VR industrial solutions providers.

Develop Customized VR Training Modules:

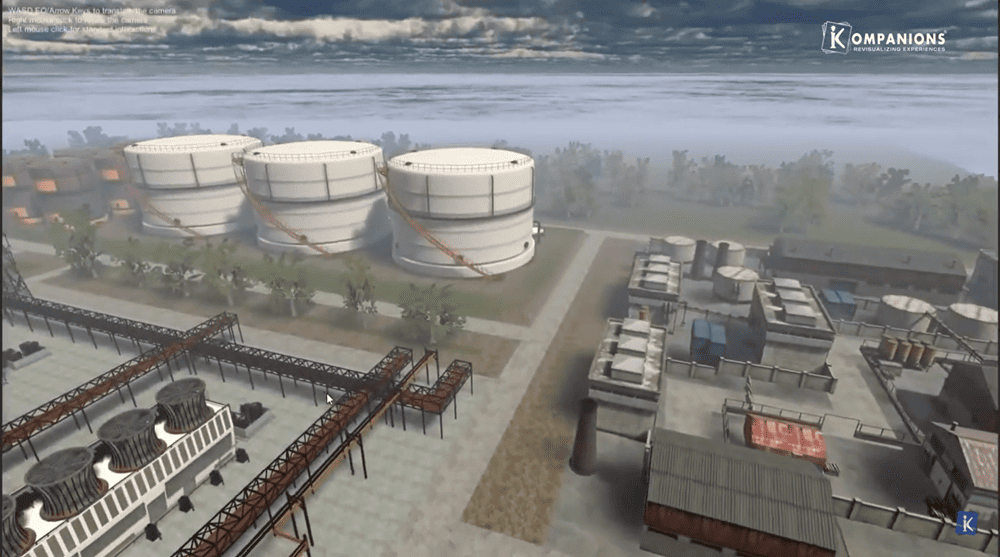

- Tailor simulations to specific workplace hazards and scenarios.

- Incorporate workplace hazard prevention principles into the training content.

- Include emergency response training scenarios to prepare workers for unforeseen events.

Upgrade the Existing Safety Programs with VR Training:

- Integrate VR training with classroom and on-the-job training.

- Employ VR to support primary safety principles and techniques.

- Track and evaluate the effectiveness of VR training programs.

Offer Regular Training and Support:

- Offer periodic refresher training to maintain employee proficiency.

- Offer technical assistance to solve any problems with VR equipment or software.

- Ensure that OSHA compliance training is kept up to date within the VR modules.

Analyze Data and Measure Results:

- Track key performance indicators, such as incident rates and training completion rates.

- Use data to identify areas for improvement and refine training programs.

- Use data from VR accident prevention simulations to improve workplace safety protocols.

Encourage Employee Feedback:

- Soliciting feedback from employees on their VR training experiences.

- Use feedback to improve the quality and effectiveness of training programs.

- Use feedback to improve industrial safety technology being applied.

Expand VR Training to Other Areas:

- Explore the use of VR for other safety-related training, such as fire safety and first aid.

- Consider using VR for military training, which also deals with high-risk environments.

- Using VR height safety training to prevent workplace injuries or fatals.

- Expand to other locations where hazardous workplace training is needed.

Bottom Line

VR Training for Hazardous Environments is an extraordinary development in occupational safety. With data-based, interactive, and predominantly immersive training experiences, VR trains employees to make well-informed choices and eliminates the risk of accidents.

As industrial safety technologies keep evolving, VR will play a more vital role in making the workplace safer for all.

At Kompanions, we harness the latest VR technology to design hyper-realistic training modules that enable industries to develop a wiser, safer, and stronger workforce.

As industrial safety technologies advance, VR will remain an indispensable factor in lowering costs, reducing risks, and guaranteeing a safe workplace for everyone.