How IIoT is Transforming the Oil and Gas Industry

Manufacturing has seen digital transformations shake up many industries as practices and tools have evolved. It’s been a long time coming in certain fields, and the adoption of digital technologies for manufacturing processes has had several factors guiding it.

For instance, according to a survey by McKinsey, the Covid-19 pandemic accelerated this adoption rate by around seven years, propelling digital technologies and the Industrial Internet of Things.

The pandemic disrupted supply chains, increased fluctuating demands, and many manufacturers operated with a reduced workforce. These challenges brought up the need for flexible and efficient processes, playing into the requirement for Industry 4.0 and other digital technologies.

As the adoption of tech and the Industrial Internet of Things climbed higher, the McKinsey survey also discovered that this phenomenon was not mainly about cost savings. In fact, only 10% of the oil and gas executives considered the upgrades as a means to reduce spending.

Meanwhile, over 50% of the executives admitted to investing in them for the competitive edge and industrial advantage they’d receive by focusing on the Industrial Internet of Things – all because they viewed Industry 4.0 as a major determining factor for their business and being core to their company’s strategy.

So today, with more oil and gas companies joining this fray, it’s important to focus on how Industry 4.0 is transforming these industries: How it has evolved and where it is headed.

Understanding IoT and Industrial Internet of Things

The Internet of Things expands how we interact with the Internet or be assisted by it beyond the usual devices like smartphones and laptops. They may consist of smart technologies that can use sensors and digital clouds and chain together multiple uses for increased efficiency.

The Smart TV is an excellent example of an IoT device. It can sync up with other devices, display live TV or OTT content, record your favorite shows and even let you resume from where you left off on other devices like your computer or phone.

The Industrial Internet of Things refers to the use of IoT technologies in manufacturing hubs and industrial settings. Mainly, it works to create a smarter and more efficient process.

Unlike the consumer IoT devices we see daily, IIoT involves connecting machines and sensors, including various tools and instruments, to the internet. It enables companies to optimize their operations while collecting and integrating data from various sources such as sensors, equipment, and machines.

It also allows industry leaders to focus on other facets like SaaS software development, using advanced technologies for predictive maintenance and machine learning.

Bringing Industrial Internet of Things to Major Industries

The Industrial Internet of Things has the potential to revolutionize several major industries in today’s day and age. More so, as we are already seeing some of the key sectors and companies in those fields implementing IIoT solutions, and there are many more that are poised to follow suit in the near future.

Let’s take a look at some of these industries:

1. Energy and Utilities:

One of the major ways in which the IIoT services and their application can help manage energy production and its distribution is by improving the utilities managing the power grids.

Upgraded to be more efficient, this can reduce the amount of energy wasted while performing basic tasks at plants and stations while improving safety protocols as smart meters, sensors, and other advanced tools become implemented.

2. Manufacturing:

Coupled with real-time equipment monitoring, manufacturing industry leaders can rely on these digital technologies to prioritize quality control and reduce the downtimes they may face in the long run.

By integrating augmented reality in manufacturing processes, manufacturers can visualize complex workflows, identify potential bottlenecks, and make informed adjustments in real time.

This not only enhances operational efficiency but also accelerates production timelines by providing step-by-step AR-guided instructions for machinery operation and assembly tasks.

With such innovations, the industry can significantly speed up manufacturing processes, optimize resource utilization, and maintain high standards of precision and quality.

3. Logistics and Transportation:

Outfitting IIoT devices and equipment into systems managing logistics and transport facilities, whether for the public sector or private companies, poses some great opportunities.

Supply chain disruptions could soon be a thing of the past, with the Industrial Internet of Things improving overall supply chain visibility and optimizing the routes of transport across various means.

Warehouse management is another part of logistics that can see upgrades as more sensors and GPS tracking tools are used to enhance how companies operate their warehouses.

In general, many industries that rely on complex systems, machinery, and production processes can benefit greatly from adopting IIoT solutions – Digital technologies crafted to help reduce the overall effort and resources needed to deliver a high-quality product and service.

Transform your operations with the power of IIoT. From efficiency to innovation, let’s unlock new possibilities for your business. Discover how IIoT can work for you.

Contact UsHow is the IIoT Changing the Oil & Gas Industry?

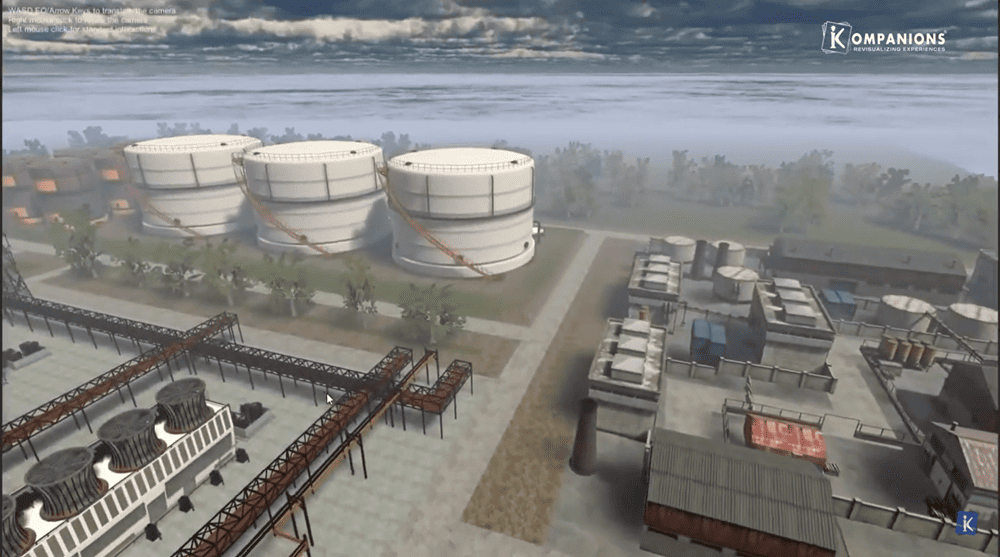

With the global demand for energy and power sources expected to grow by about 25% by 2040, there has never been a more important time in recent years for companies to adopt IIoT solutions.

Learning to deal with demand fluctuations and other challenges, the experiences have proven that energy companies need to digitize and become more agile in the process. And here’s why many companies are beating the odds to scale with new technologies:

1. Real-time Monitoring:

IIoT devices and tools equipped with smart sensors and interfaces are able to assist in monitoring oil and gas operations as they unfold.

This provides the staff and skilled journeymen with the information they need to gauge how the production is proceeding, along with any maintenance or safety check requirements.

2. Predictive Maintenance:

As with enhanced monitoring practices, IIoT-enabled equipment and tools with sensors also enable energy companies to look out for any machines breaking down or equipment failures.

_64505.jpg)

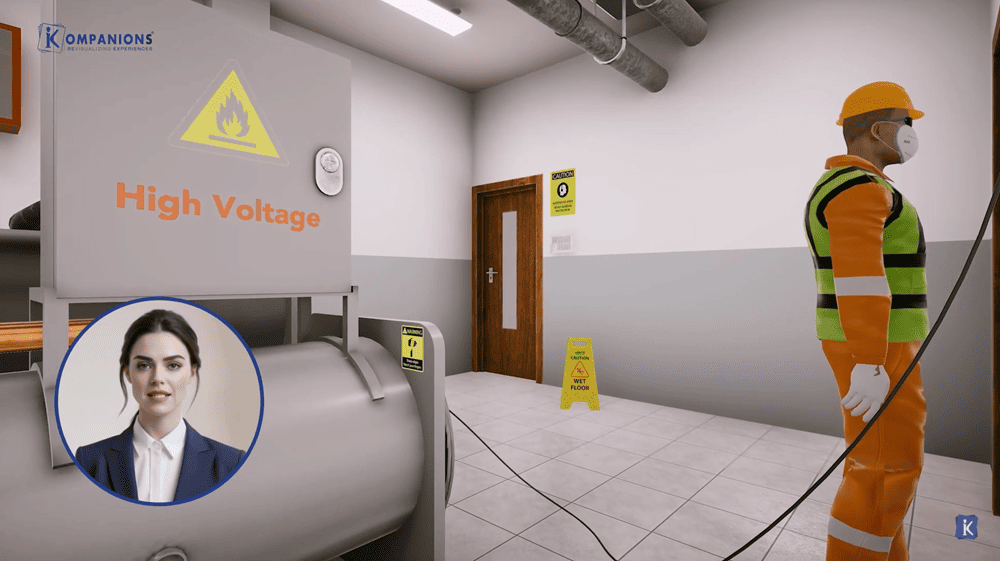

By allowing to check for these instances with predictive maintenance before they have even happened, there are lower chances for downtimes and accidents owing to better safety measures.

3. Remote Work Operations:

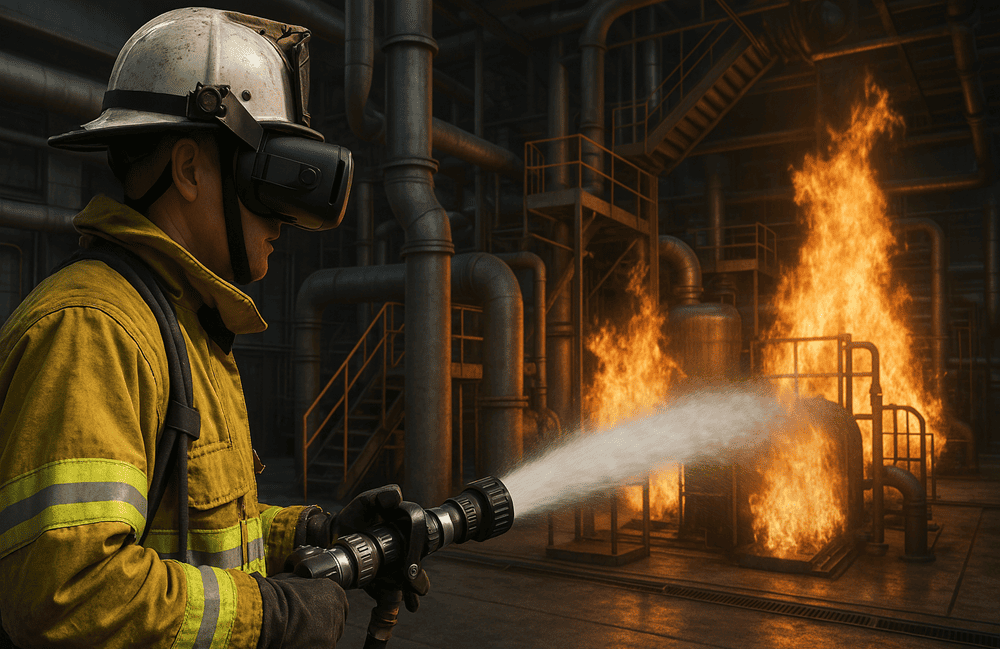

Stepping up the focus on safety measures as with SaaS security, the Industrial Internet of Things shifts companies onto using equipment and devices enabling remote work.

Machines are outfitted to complete tasks and processes of energy production and manufacture, which may otherwise require human operators in hazardous environments. This further reduces room for accidents and errors, along with mechanizing the tougher parts of the manufacturing processes.

4. Improved Production Levels:

The IIoT phase of upgrades to the oil and gas companies improves production levels and maximizes the efficiency that can be achieved in the trade. From providing live data on the condition of wells and the ongoing work to how the reservoir is performing, there’s an array of devices dedicated to this segment for businesses.

Energy companies can rely on an Industrial IoT development company to help maximize their output by adjusting production levels per their resources and minimizing waste.

5. Environmental Impact:

One major benefit of IIoT and AR/VR to oil and gas companies as well as to nature is the overall reduction in conditions that threaten the environment.

With smart devices and equipment already minimizing production issues and accidents, specialized applications can help track and monitor the environmental impact of the production process.

Revolutionize your oil and gas operations with IIoT solutions. Boost safety, efficiency, and profits by starting today! Explore IIoT solutions now.

Contact Us6. Reduced Expenses with Industrial Internet of Things:

As a combined effect of the other processes from above and with the passive improvement to efficiency levels and resource management. The Industrial Internet of Things effectively reduces the costs for energy companies and increases their profits – Further enabling businesses to manage supply and demand fluctuations which are almost certain to arise as part of the trade experience.

The size and complexity of energy companies, especially those in the oil and gas trade, have often left little room for any major form of digital technologies to get adopted.

Any transformation to their production work could have normally felt like a monumental shift with not an equally large payoff. But that isn’t the case or matches the current scenario anymore.

Oil and gas producers may have lagged behind, but they are now on track to catch up with other industries. Like any other manufacturer, they have felt the winds of change and have taken strides to remain competitive in today’s markets.

Today, the Industrial Internet of Things is transforming the Oil and Gas industry in leaps or at least in sizable increments. Digital technologies are seeing moderate investments, with about 80% of oil and gas executives leading the venture into adopting smarter equipment and devices.