Role of Digital Twin Technology in Modern Manufacturing

Global industries are striving toward digital transformation. Enterprises are trying on nearly all the advanced technologies to speed up their digital transformation journey.

Undoubtedly, the linkage between the physical and digital world is playing the role of the catalyst in the digital transformation efforts of industries worldwide.

Sectors like gaming and entertainment, manufacturing, automotive, and education, to name a few, have already embraced industrial AR/VR solutions in their business operations. On one side, the metaverse gives a new shape to how people have been counting on virtual reality.

While on the other side, another player is emerging on the surface, reinforcing the values of immersive technologies like AR and VR, 3D modeling, IoT, and other advanced technologies across industries. It is Digital Twin technology.

If you scout the internet, you will see that the curiosity around digital twins is growing more and more. And why it shouldn't be? Digital Twin technology is crucial in enhancing the convergence of the real and digital worlds merging.

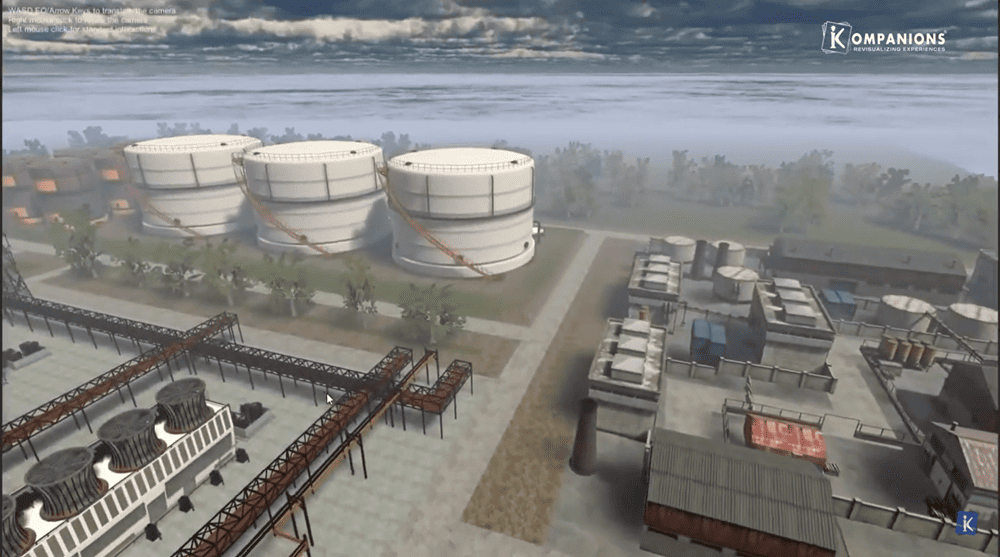

Digital Twin enables organizations to create digital copies of their products, assets, and production processes so that the manufacturing sector can squeeze the most out of it.

Digital twins in manufacturing will not just help manufacturers create a digital replica of their products. By developing the digital replica of products and assets, the technology will aid businesses in optimizing performance and maintenance overall.

With Digital Twin in manufacturing, businesses can replicate their products as well as manufacturing processes. Here, we will define Digital Twin, its benefits, types, and the importance of Digital Twin.

What is Digital Twin Technology?

- Digital Twin is the virtual representation of physical objects and processes.

- Digital Replicas can revolve around products, processes, people, assets, and many more.

- Real-time data through sensors placed in the real process creates these digital representations.

Technologies like Artificial Intelligence, Machine Learning, Augmented Reality, Virtual Reality, IoT, etc.., are the pillars of Digital Twin technology. It allows companies to simulate the behavior of objects and predict how the thing or the process will work in a real-world scenario.

Digital Twin in manufacturing can represent either products or processes.

- So, digital product twin mirrors all the physical parts of products virtually.

- The products can range from electronics and mechanics to software.

- The digital representation allows businesses to simulate the myriad situations of the manufacturing process.

So, whether it is a new product or production process, Digital Twin in manufacturing allows organizations to validate and test the business process and products from every possible angle.

In addition, the digital twin version of products and processes can vary from simple to complex, depending on the components of the products or processes. If manufacturers intend to build a simple product, its digital twin will also get a simplified version.

On the other hand, if the virtual twin represents a complex business process, production process, or product along with the complexity of the data, the twin becomes a complex one.

Types of Digital Twin

Digital twins in manufacturing can represent multiple things. On this basis, we can categorize Digital Twin into four types:

- Parts Twining

- Product Twining

- System Twining

- Process Twining

1. Parts Twining

The robust parts twining enables engineers to understand the characteristics of the part in detail. Whether mechanical, electrical, or software, a virtual twin of parts allows engineers to get a complete idea about the part's characteristics and efficacy.

Through 3D simulations, companies can make predictions regarding the real-world behaviors of the parts under different circumstances.

2. Product Twining

Digital Twin in manufacturing gives manufacturers a deep insight into their products. Product twining enables manufacturers to look into all the parts of the product and analyze how they work together, interacting with each other.

3. System Twining

System twinning allows engineers to operate and maintain entire fleets of disparate products that work together to achieve a result at a system level. It will help manufacturers attain peerless efficiency and efficacy, monitoring the entire system virtually.

4. Process Twining

Products and assets can not restrict the efficacy of Digital Twin technology. Manufacturers can also twin their business processes and production processes to optimize their business operations.

Manufacturers can monitor and optimize their key business metrics with a more data-driven approach with Digital Twin.

What are the Uses of Digital Twin?

A virtual twin can replicate anything from offshore oil platforms to automotive manufacturing processes. The following are the most promising uses of digital twin technology:

1. Supply Chain

- Packaging materials' performance prediction

- Shipment protection enhancing

- Optimizing warehouse design

2. Healthcare

- Healthcare experience visualization

- Optimizing patients' experience

- Optimization of performance

- Improving healthcare operational efficiency

3. Manufacturing

- Increasing product development efficiency

- Effortless customization of product design

- Improving shop floor performance

Related post: HoloLens in Manufacturing: Use Cases of Speeding Up Manufacturing Through AR

4. Retail

- Improving customer experience

- Optimizing store layouts and product placement

- Personalizing marketing and shopping experiences

- Predicting maintenance and reducing operational costs

5. Construction

- Enhancing Project Planning and Visualization

- Real-Time Monitoring of Construction Progress

- Improving Collaboration and Communication Across Teams

- Predictive Maintenance and Risk Management

- Optimizing Resource Allocation and Reducing Waste

Integrating digital twins for construction enables real-time simulation of projects, improving decision-making and reducing delays.

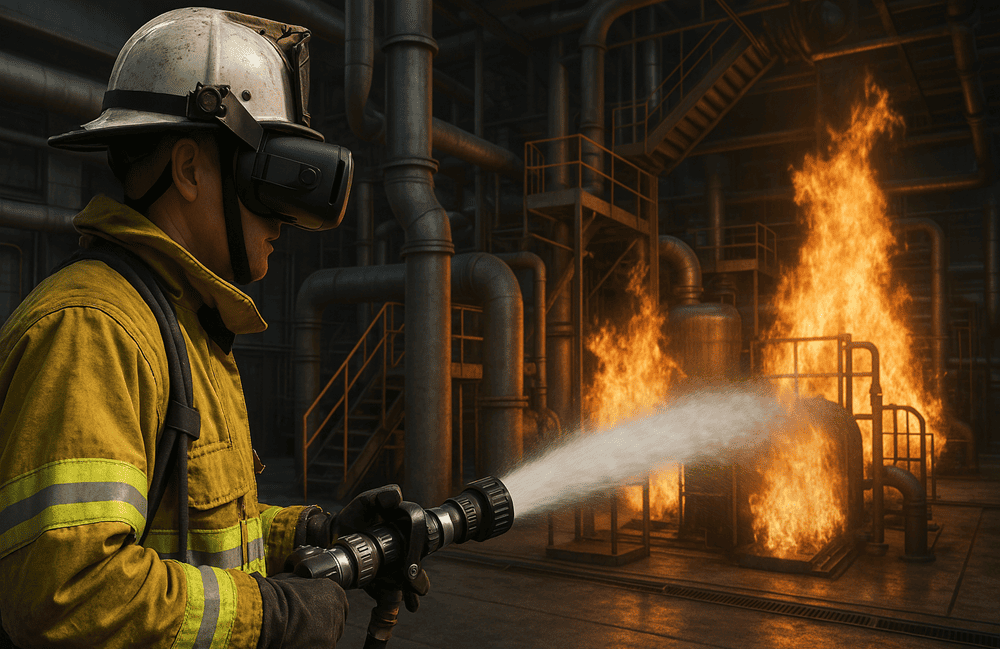

Importance of Digital Twin in Manufacturing

Virtual reality in manufacturing helps in the creation of product twins to simulate the real-world environment, create remote collaborations, etc. The implementation of Digital Twin in manufacturing will allow manufacturers to leverage the following benefits:

1. Refining Product Quality

- IoT sensors attached to the physical products generate real-time data.

- Through these sensors, businesses can analyze and detect problems within their systems.

- Consequently, organizations can fine-tune their product quality with the digital twin approach.

2. Risk Management

Which areas of the manufacturing process require more optimization or which part of the product will fail becomes clear with digital twin implementation.

It will minimize the risks associated with the manufacturing process and even the products.

3. Improving User Experience

Digital twin technology enables manufacturers to get deep real-time insight into the physical system, even during production. Engineers or workers can remotely access the technology to monitor the system's performance.

When operational efficiency reaches its peak, the user experience undoubtedly gets better.

4. Product Development Process Getting Simplified

With Digital Twin technology, manufacturers do not need to develop physical prototypes of products. It reduces the overall development cost, accelerating the time to market. Digital Twin simplifies the manufacturing process.

Conclusion

To conclude, Digital Twin in manufacturing is essential for manufacturers to mold their business operation and production process in Industry 4.0.

The technology leverages real-time data to establish and illustrate 3D simulation that aids organizations in predicting the product or process efficiency and performance.

So, it enhances the functional objectives of the manufacturing systems. This novel technology enables manufacturing organizations to merge real-world and virtual factory environments to gain deeper visibility into their production processes and products.

Still, not clear?

To learn more about Digital Twin technology, contact KOMPANIONS.