Digital Twin in Oil and Gas Industry: Use Cases, Benefits, and Examples

The oil and gas industry operates in a high-risk, high-stakes environment where safety, efficiency, and cost-effectiveness are paramount. Digital twin oil and gas solutions are transforming the sector by providing real-time insights, predictive analytics, and operational optimization.

This blog explores the role of digital twin technology in oil and gas, its use cases, benefits, and real-world examples that illustrate its impact.

What is a Digital Twin in Oil and Gas Industry?

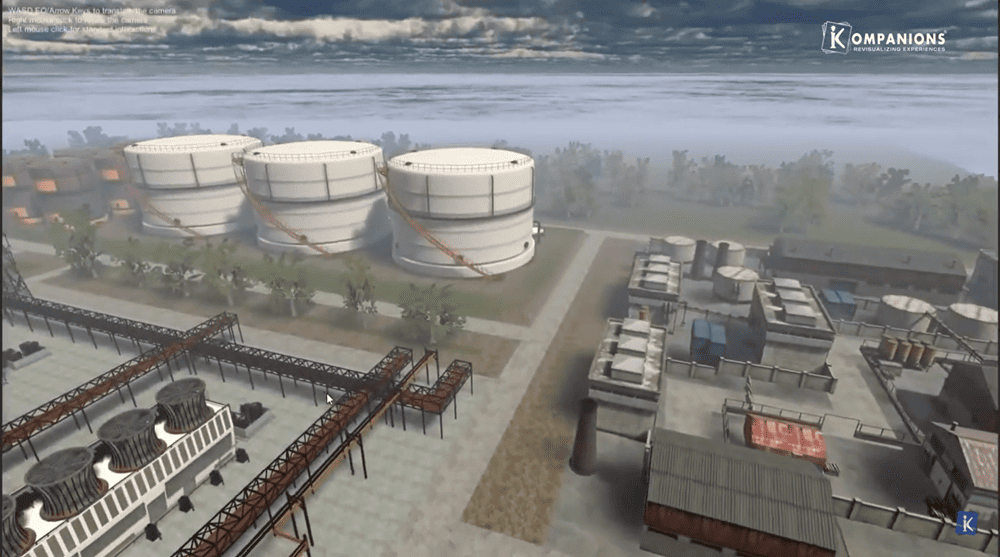

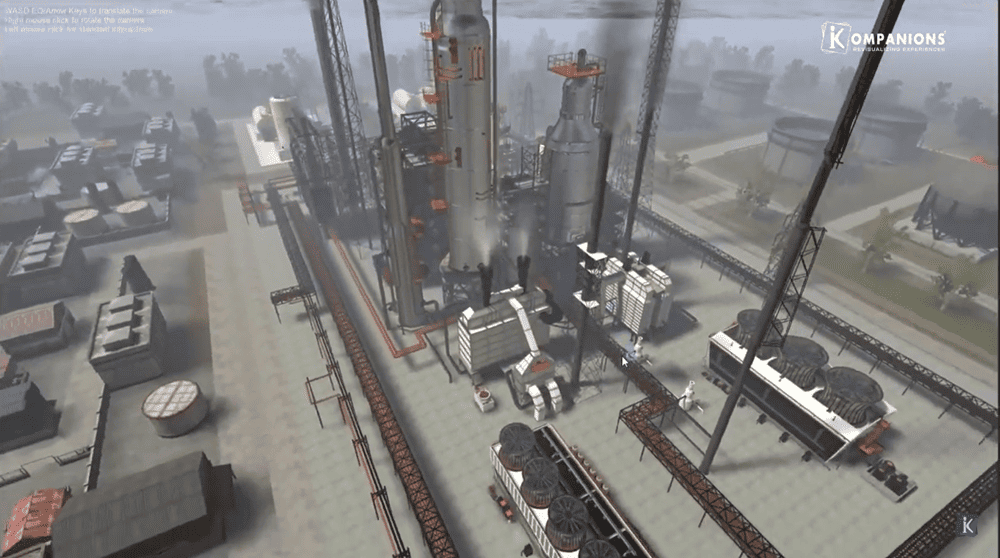

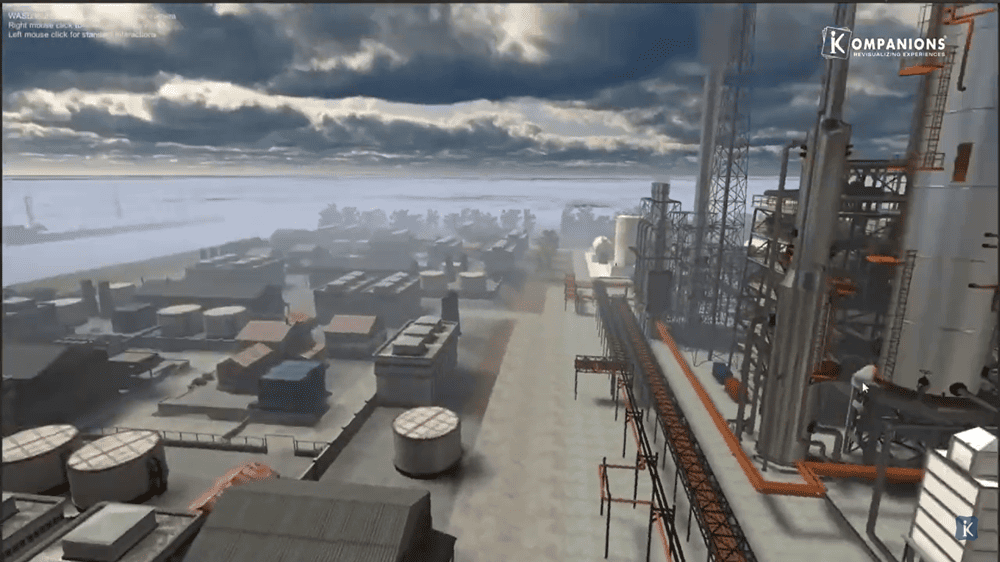

A digital twin in the oil and gas industry is a virtual representation of a physical asset, process, or entire facility. It mirrors real-world conditions using data from IoT sensors, AI, and cloud computing to enable real-time monitoring and simulations.

A digital twin in the oil and gas industry is a virtual representation of a physical asset, process, or entire facility. It mirrors real-world conditions using data from IoT sensors, AI, and cloud computing to enable real-time monitoring and simulations.

These digital replicas help operators optimize performance, enhance safety, and reduce downtime.

Digital twins serve as a bridge between the physical and digital worlds, allowing oil and gas companies to make informed decisions based on real-time and historical data.

By leveraging this technology, businesses can create highly efficient, resilient, and sustainable operations.

Key Benefits of Digital Twin Technology in Oil and Gas

Digital twins bring a multitude of advantages to the oil and gas sector, transforming how companies manage assets, workflows, and risk. From operational efficiency to predictive maintenance, the benefits are far-reaching.

1. Improved Operational Efficiency

By continuously collecting and analyzing data, digital twins provide real-time insights into asset health and performance. This helps in predictive maintenance, reducing unexpected failures and costly repairs.

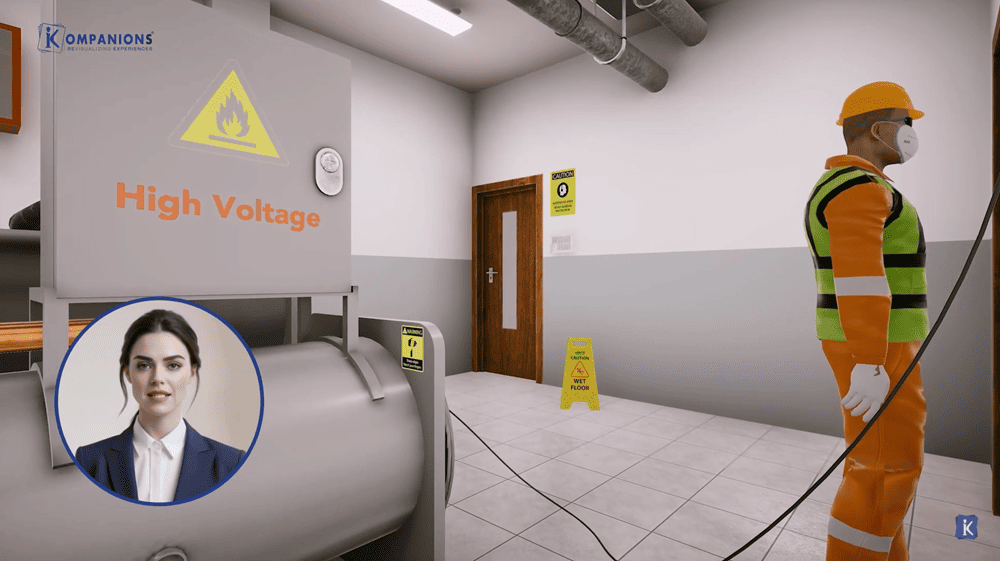

2. Enhanced Safety and Risk Management

Oil and gas operations involve hazardous environments. Digital twins enable virtual testing of processes, minimizing risks before implementing changes in the real world.

3. Cost Reduction and Increased ROI

Optimizing workflows, reducing maintenance costs, and preventing downtime contribute to significant financial savings over time.

4. Sustainable and Environmentally Friendly Operations

By optimizing resource use and reducing emissions, digital twin solutions help companies align with sustainability goals and regulatory compliance.

Digital Twin Use Cases in Oil and Gas Industry

The oil and gas industry is increasingly adopting digital twin technology across multiple applications, from asset monitoring to workforce training.

Below are some of the most impactful use cases where digital twins are making a difference.

1. Predictive Maintenance for Equipment

Oil rigs, refineries, and pipelines experience wear and tear. Digital twins analyze equipment conditions and predict failures before they occur, allowing for proactive maintenance scheduling.

Oil rigs, refineries, and pipelines experience wear and tear. Digital twins analyze equipment conditions and predict failures before they occur, allowing for proactive maintenance scheduling.

2. Asset Lifecycle Management

From design and construction to decommissioning, digital twins ensure that assets are utilized efficiently throughout their lifecycle.

3. Remote Monitoring and Control

With offshore platforms and remote drilling sites, real-time monitoring is critical. Digital twins enable operators to monitor equipment performance and make data-driven decisions from anywhere.

Optimize your oil and gas operations with KOMPANIONS' cutting-edge digital twin solutions.

Get a Free Demo4. Process Optimization

By simulating various operational scenarios, digital twins help optimize production efficiency and energy consumption.

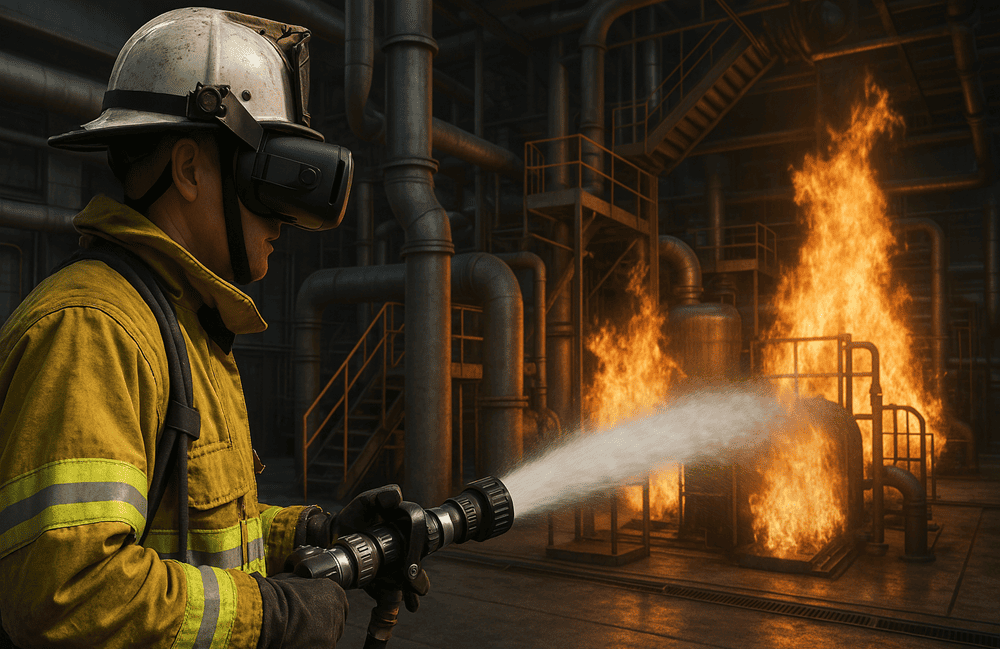

5. Workforce Training and Safety Simulations

Enterprise VR solutions integrated with digital twins create realistic training environments for oil and gas professionals. This improves safety and preparedness for real-world situations.

Real-World Digital Twin Oil and Gas Examples

Many leading oil and gas companies have successfully implemented digital twins to optimize operations and reduce costs. Below are some notable examples that highlight the impact of this technology.

| Company | Use Cases | Impact |

|---|---|---|

| BP | Offshore asset monitoring | Reduced downtime by 30% |

| Shell | Predictive maintenance | Saved millions in maintenance costs |

| ExxonMobil | AI-driven refinery optimization | Increased operational efficiency by 25% |

The Role of Emerging Technologies in Digital Twins

Emerging technologies are playing a crucial role in enhancing digital twin capabilities. The integration of AI, IoT, and augmented reality is taking digital twin applications to new heights.

• Artificial Intelligence for Energy Sector

AI enhances digital twins by providing deep learning capabilities for predictive analytics, anomaly detection, and automated decision-making.

• Industrial IoT in Energy Sector

IIoT powered oil and gas sensors feed real-time data into digital twins, ensuring accurate and continuous monitoring of assets.

• Augmented Reality for Energy Industry

By integrating AR with digital twins, field engineers can visualize real-time data overlays on equipment, improving diagnostics and maintenance.

By integrating AR with digital twins, field engineers can visualize real-time data overlays on equipment, improving diagnostics and maintenance.

• BIM with Digital Twins

Building Information Modeling combined with digital twins allows for better infrastructure management in oil and gas facilities.

Future Trends in Digital Twin Technology for Oil and Gas

As digital twin technology evolves, new trends are shaping its future in the oil and gas industry. Companies that embrace these innovations will gain a competitive edge and drive industry advancements.

- AI-powered autonomous operations – Using machine learning to enhance decision-making.

- Blockchain integration – Improving data security and transparency in digital twin ecosystems.

- Cloud-based digital twins – Enabling scalable and cost-effective deployment for global operations.

- Smart manufacturing with digital twins – Transforming asset production and supply chain logistics using manufacturing virtual twins.

- Vehicle digital twin technology – Enhancing fleet management for oil and gas transport operations.

Conclusion

The adoption of oil and gas digital twin technology is revolutionizing the industry by improving efficiency, safety, and cost-effectiveness. From predictive maintenance to workforce training, digital twins offer an array of benefits that drive innovation in high-risk environments.

As digital twin oil and gas examples continue to showcase success, more industry leaders are expected to invest in this transformative technology.

By integrating artificial intelligence for energy sector, industrial IoT in energy sector, and augmented reality for energy industry, companies can unlock the full potential of digital twins for enhanced decision-making and sustainable operations.

Need a tailored digital twin oil and gas solution? Contact KOMPANIONS today to explore how our cutting-edge enterprise VR solutions can help you optimize your operations!