AR for Industrial Maintenance: Reducing Downtime & Boosting Efficiency

The manufacturing sector is always working to boost productivity, reduce downtime, and improve operational precision. Because this sector has numerous high-risk activities, safety is a main priority.

In recent years, augmented reality has revolutionized manufacturing by enhancing efficiency and innovation and it is now impacting not only the way things are made but also the way we think about making them.

How industries maintain equipment is undergoing a fundamental shift, and augmented reality is at the forefront of that change.

That maintenance revolution is providing remote assistance, real-time instruction, and exactly what its name implies: predictive maintenance, which is becoming an increasingly important tool in the maintenance toolbox.

The Importance of AR in Industrial Maintenance

The manufacturing industry has seen a speedy transformation with the advent of augmented reality in the not-so-distant past.

Augmented reality for industrial repair and maintenance equips technicians with in-depth knowledge of intricate equipment and enables them to access it remotely.

The innovative technology goes beyond traditional maintenance practices that often depend on knowledge and physical manuals found at a specific job site but uses digital overlays to enhance precision and speed.

Benefits of Augmented Reality in Maintenance and Repair

AR is transforming maintenance and repair by providing real-time guidance, improving accuracy, and reducing downtime. AR enhances troubleshooting, streamlines workflows, and boosts efficiency, making complex repairs faster and more cost-effective.

1. Reduced Downtime

AR optimizes productivity with lowered downtime. Devices driven by AR assist employees with gaining detailed information pertaining to machines and equipment promptly.

2. Improving Productivity

Augmented reality maintenance of equipment increases performance with real-time data. The equipment can track and analyze performance, including vibration, pressure, and temperature, which makes it easy to identify faults early and repair them.

3. Enhanced Efficiency

Augmented reality equipment maintenance effectively addresses workplace accidents and risks. It prevents accidents and injuries by giving an early warning.

By seeing risks in real time, staff members avoid routine maintenance risks. AR provides immediate safety alerts so workers remain vigilant for threats.

4. Remote Assistance

Technicians can help on-site staff through industrial augmented reality interfaces, reducing travel time. This delivers rapid troubleshooting and prevents operations from being interrupted.

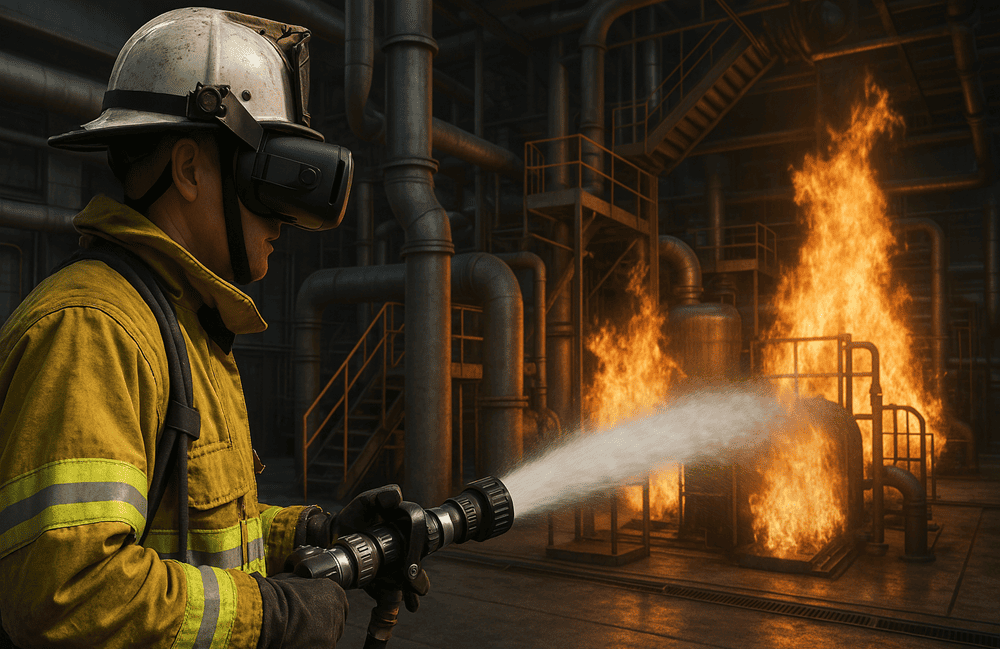

5. Enhanced Training

Augmented reality maintenance training allows new hires to learn through interactive simulations rather than passive learning. It leads to faster skill development and better retention of maintenance procedures.

6. Predictive Maintenance

Augmented reality when used with the sensors, helps in the early detection of any damage or failure in the ongoing operation. This helps in the prevention of injury or accidents in the workplace and also enhances the life of equipment.

Minimize downtime and maximize efficiency with cutting-edge AR solutions for industrial maintenance!

Get StartedOptimizing Repair & Maintenance with AR

You must grasp industrial AR technology to cut downtime, shorten training, ensure accuracy, boost safety, or do more with the same resources.

1. Troubleshooting and Repair

One of the primary advantages of Augmented reality for maintenance and repair is that it offers real-time access to equipment schematics and detailed instructions.

These are laid on the equipment directly as the technician works on it. All of it meshes well with their understanding of the real gear. Technicians can easily identify problems with this additional information. They can repair machines quickly, cutting costly downtime.

2. Training and Knowledge Transfer

Industrial augmented reality helps in training purposes. The technicians can practice procedures and simulate real-life scenarios. AR for training can offer hands-on experience on the actual machine by offering a proper workflow and techniques and allowing sessions with instructors.

The learn-by-doing approach helps trainees to get a better understanding of all the machinery.

3. Quality and Precision

For several industrial maintenance operations, precision and quality are the most important parameters for safe and efficient operations. AR for workplace safety plays a crucial part in this as it overlays accurate guidelines, tolerances, measurements, and other data directly onto the work surface while guiding technicians each step of the way.

The holistic approach helps technicians to ensure precise and safe operations, mitigating the challenge of risks in tasks.

Upgrade your operations today, contact us to see how AR can revolutionize your maintenance workflow!

Get StartedTransforming Railway with Predictive Maintenance and AR

Railway operators are integrating industrial augmented reality with predictive maintenance to enhance fleet reliability. AR helps inspectors visualize and track defects, monitor wear on components, and streamline repairs. This proactive approach has resulted in fewer delays and improved passenger safety.

What the Future Holds

Industry 4.0 has seen many transformations in technology in recent years, but AR is believed to be one of the most significant developments among them all.

As AR technology grows, businesses will increasingly implement augmented reality for maintenance and repair to streamline their operations. Future developments may include:

- AI-Powered AR Diagnostics: Machines will self-diagnose issues and display AR-generated solutions.

- Voice-Controlled AR Interfaces: Technician efficiency will be enhanced through hands-free interaction.

- AR-Enabled Collaborative Workspaces: Multi-user AR environments will enhance team coordination.

Bottom Line

The industrial equipment maintenance and repair field has gained massive importance in recent years. With the rapid adoption of technologically advanced solutions in the field, operations are becoming safer and more precise.

Augmented reality for maintenance has set its foot in the industry by offering benefits such as improved training, lowered downtime, and, most importantly, enhanced safety.

Businesses implementing AR-based solutions for equipment maintenance will benefit from reduced operational costs and enhanced productivity.

Effective training with AR-based techniques will also ensure safety and effective disaster management at the workplace. AR is all set to change the face of the industry with its holistic approach and risk-free operations.